Challenge tool changer

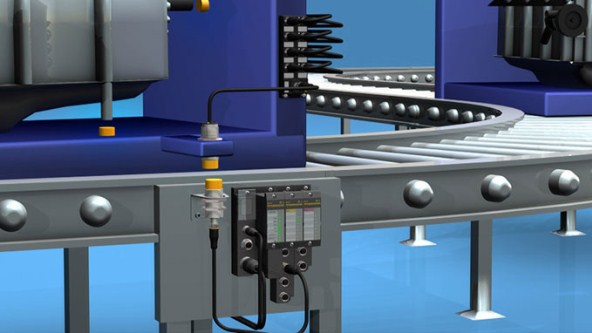

Robotic tool changer with IO-Link

Several connections are required between the fixed machine component and the tools: as well as being connected mechanically, the two components also need to transmit power and I/O data.

For this reason, the electrical connections require multi-pin plug connectors and multi-core cables. These connections are placed under heavy strain by the high frequency of the mating cycles and must guarantee a high level of contact reliability. The consequences are high purchasing costs and production downtimes due to wear and tear. One alternative to this solution is to use contactless inductive couplers to transmit data and power.

Your Benefits

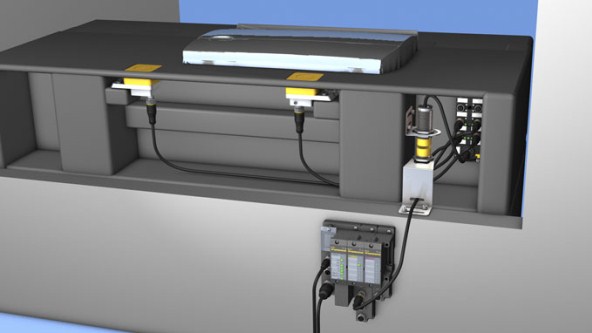

- The combination of I/O hub and inductive coupler transmits up to 16 switching signals

- Inductive couplers transmit up to 12 watts of power without requiring a contact medium

- The workpiece carrier can be identified using the I/O hub

Further Information

Select Country

Turck worldwide

-turck-image.jpg)

-turck-thumbnail.jpg)